|

Andy Connor & Wilson Siringoringo, Auckland University of Technology, New Zealand

andrew.connor@aut.ac.nz, wilson.siringoringo@aut.ac.nz

Nick Clements & Nick Alexander, Building Integration Services Company (bisco), New Zealand

nickc@bisco.co.nz, nicka@bisco.co.nz

Connor, A., Siringoringo, W., Clements, N., Alexander,

N. (2007, Dec), Building Services Integration: A Technology

Transfer Case Study. Bulletin

of Applied Computing and Information Technology Vol. 5, Issue

2. ISSN 1176-4120. Retrieved

from

ABSTRACT

This paper details the development of a relationship between Auckland

University of Technology (AUT) and the Building Integration Software

Company (bisco) and how projects have been initiated that add value to

the bisco product range by conducting applied research utilising

students from AUT. One specific project related to producing optimal

layout designs is discussed.

Keywords

Technology Transfer

1. INTRODUCTION

Technology transfer is the process of developing practical applications

for the results of scientific research. In other words, the aim of

technology transfer is to ensure that the knowledge generated through

research has commercial value and that the knowledge itself is moved

from the research domain into the industrial domain. The Technology for Industry Fellowships offered by Technology New

Zealand are one mechanism for promoting technology transfer as well as

developing students' skills and knowledge within commercial R&D

environments that are relevant to their expertise. To utilize this funding source to its full advantage,

there is a need to establish a relationship between the academic

institution and the company, and to develop a shared understanding of

aspirations and how the project can be designed to allow all of these

aspirations to be met.

2. THE BUILDING INTEGRATION SOFTWARE COMPANY

Building Integration Software Company (bisco) Ltd is a business

enterprise whose main product is information management software for the

residential house construction industry. The organization has been

founded by people who had identified the need of such centralized

information management from their own extensive experience in the

construction industry. The premise of such a need is the fact that a typical house building

project involves a number of different parties such as an architect,

builders, city council, and others, who work in different ways and run

their organizations for different goals. Although many have already

adopted computer-based information systems, there is no automated means

for communication with other parties. Only verbal and paper-based forms

of communication are hitherto available to those parties to exchange

information. It is not surprising that substantial amounts of money and

effort are wasted during a project due to the lack of reliable and

efficient communication systems.

The core business of bisco is developing software to accommodate such

communication needs. At the time of the writing, the prototype of the

software is drawing close to finish, after which it will undergo a

series of live tests before it is finalized for release to the market.

The software has been given a commercial name bisco Office™. bisco Office™ manages a range of information that is very diverse in

terms of representation and usage. A typical bisco Office™ database for

a house building project will include pictures and text, Computer Aided

Design (CAD) drawings, letters, invoices, and a host of other documents.

Such documents take various physical forms such as computer files,

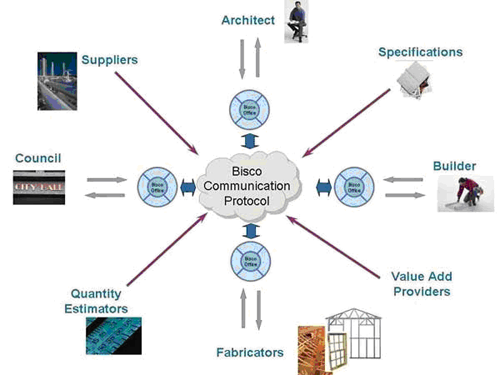

paper, and e-mail correspondence. Figure 1 shows the different parties

interacting through the bisco Office™ software.

Figure 1. Information exchange using bisco Office™

software

The geometric data stored in the CAD drawings assumes overriding

importance in the house building project’s web of information. Many

important documents created during the lifetime of the project, such as

cost estimates, specification documentation, or project plans, are

actually spawned from the CAD models. Consequently, the software

engineering aspect of bisco Office™ at the current stage revolves

primarily on extracting and making use of the CAD data.

The bisco Office™ product provides a framework for improving

information exchange in the building services industry and for

integrating existing tools in a more efficient manner. The framework

also allows for the integration of new tools, such as the material

optimisation approach outlined in section 3. However, the success of the

approach depends on its ease of use and therefore a usability study is

being undertaken which will be detailed in future publications.

3. MATERIAL LAYOUT OPTIMISATION PROJECT

3.1 Overview of Project Scope

Optimum two-dimensional layout is a class of problems encountered in

many industries. The problems are characterized with the need to pack

non-overlapping shapes in an enclosed plane with the aim of minimizing

the area outside the boundaries of the shapes, therefore maximizing the

utilization of the material in the base sheet. The two-dimensional

layout problem exists in several variants. Among them are the sheet

layout problem, bin packing and strip packing problems,

optimum floor

plan problem, and cutting stock problem.

The optimum two-dimension layout problem has an application in a wide

range of industries. Industries such as textile, wood, glass, and

steelworks regularly encounter the problem of cutting the material most

efficiently so as to minimize waste. In a different context, very large

scale integration (VLSI) design requires arranging a large number of

transistors and other modules in a rectangular silicon chip.

A rather unique variant of the optimum two-dimensional layout problem

is found in the construction industry. A polygon shaped area such as

wall or ceiling is to be tiled with covering sheet material such as

Gibraltar board or plywood. With such tiling, it is essential that the

entire surface is covered with no gaps or overlaps. The panels are

obtained from the supplier in a range of fixed size rectangles.

Typically the individual panel is much smaller than the area to be

covered. It is also anticipated that the enclosing area may have an

irregular outline.

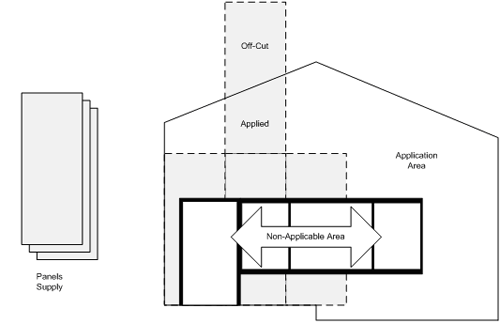

The problem is demonstrated in Figure 2. To keep the construction

expenses under control, the builder must arrange the panels in a way

that keeps the cost variables low. Such parameters include the number of

panels allocated, the amount of discarded off cuts, and the amount of

effort required for cutting the panels.

Figure 2. Wall overlay with fixed size panels

A similar problem has been encountered in the shipbuilding industry,

particularly in cutting steel sheets to cover various parts of the ship.

Adamowicz and Albano defined the problem for the operator (Adamowicz &

Albano, 1976):

- A set of standard rectangular sheets of steel is provided

- An order is given to produce various types of shapes which include

rectangular and irregular shapes

- It is required that no two shapes may overlap

- Waste is minimized

When the panel is homogenous, such as with sheet metal, it is

desirable to reuse the off cuts to cover irregular regions at other

places, as this has the potential to reduce the total number of sheets

required. A particular example was made by Sibley-Punnett and Bossomaier

(2001) regarding the reuse of off cuts from corrugated iron roofs. The

justification for such effort is provided by the high cost of delivering

the roofing material.

The diversity of materials used for constructing a building provides

no guarantee that such homogeneity exists for materials used for a

particular area. The implication is that the constraints for a

particular section of the building cannot be predetermined. In response,

a computer program used to resolve such problem must be capable of

finding the solution under a varying set of constraints to allow it to

be used for any specific instance of the general problem.

Closer examination reveals that the polygon overlay problem is

composed of two sub-problems which must be resolved sequentially,

although each sub-problem still belongs to the same two-dimensional

layout optimization. For a given enclosed area and a given dimensions of

rectangular panels, the requirement is twofold:

- Find the optimum arrangement of whole panels in which the covered

area within the enclosure is maximized. The by-product of this process

is a set of irregular shapes which represent the remaining exposed

areas.

- Resolve how such irregular shapes can be nested within the minimum

number of panels. Shapes that are bigger than the panel itself are cut

at angles parallel with the rectangle’s axes to allow such nesting.

This decomposition into two sub-problems can potentially mask the

complexity of the task of finding the optimum solution. It is important

to recognize that in the construction industry, the actual size of the

panels is in itself a design parameter. In some applications, the panel

size will remain fixed for the two sub-problems whilst for other

applications the panel size could potentially be varied. With this in

mind, it becomes apparent that the problem is complex with potentially

many locally optimum solutions.

At the end of the calculation process, the desired output consists of

numerical and graphical information:

- The total number of panels, consisting of panels to be fitted whole

and the remainder to be cut to produce the irregular shapes

- The nesting plan with which irregular shapes are cut from whole

panels

- The area overlay plan with which whole panels and irregular cuts are

fitted to the enclosed area

It is important to note that although the two sub-problems are

similar, they are resolved with mutually unrelated and potentially

conflicting objectives. As an example, the lowest cost solution for

first sub-problem may be to cover as much area as possible with the

least number of panels. However, the optimum solution for the second

sub-problem may be the least amount of cutting (the panel may actually

be a marble or granite slab, for instance). Hence a cheap solution in

the first phase may lead to expensive penalties in the second.

3.2 Project Motivation

Apart from reducing the waste and reducing the associated cost,

automating the panel placement design also greatly assists the builder

in calculating the required material. When the calculation is done by

hand, the common practice is to have a human expert work on the layout

and to estimate the number of panels needed to cover a particular part

of the building. A few extra panels must then be provided to anticipate

the error in the calculation. As the solution only applies to a particular part of the building,

the work must be repeated for all other parts as well. The process

becomes more tedious when different sizes of the panels are available to

choose from. Exploring more than a few different configurations by hand

is therefore an impractical proposition.

In general, the cost of the materials is low so that the additional

time required to optimise the panel layout manually cannot be justified

by the potential cost savings.

The low value means even using computer optimisation would not be

viable should it require additional work.

As bisco Office™ makes the required geometric and building

information easily available for use by an optimisation function the

process becomes a viable option.

Another inherent problem in complex problems is the lack of guarantee

that an optimum solution in the first phase will lead to an optimum

solution of the entire problem. Coupled with the absence of a-priori

knowledge about the cost of the subsequent phase, exploring the

less-than-optimum first-phase solutions becomes a necessity. Seen in

this light, making the process automatic offers the potential of

discovering better solutions than those obtained by hand.

When computers are used, more possible solutions can be explored both

for individual parts of the building as well as the sum of all those

parts. The desired effect is that by providing the raw information to

the software, in the form of a CAD model of the entire building, the

builder obtains a detailed and accurate plan about the number of panels

required and how they should be cut and installed for the whole

structure. In addition to this, some suppliers offer to package the sheet

materials into “room lots” allowing their placement by crane into the

room space prior to the erection of the building walls saving labour

carrying the individual sheets by hand.

Use of this technology will allow the use of length optimised

packets increasing the effectiveness of this service.

3.3 Project Achievements

The project has been a great success with regards not only the

outcomes of the research, but also in terms of transferring research

knowledge into the industrial domain. Initially, the research focused on

the underlying geometric operators required to manipulate the CAD data

and panel shapes to allow the optimisation process to be realised. The project also developed a range of algorithms that could be

applied to the solution of layout optimisation problems in the building

services domain. A comparative study has been undertaken to see which of

the algorithms best meets the needs of the industry and this will be

taken forward in the commercialisation phase of the project.

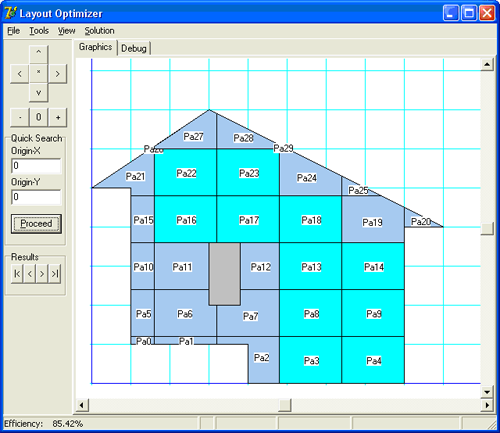

A software tool to perform the layout optimisation has been

developed, as shown in Figure 3.

Figure 3. Layout optimisation software tool

3.4 Project Status

This project, which is now complete, has been undertaken by a student

on the Master of Computer and Information Sciences programme at Auckland

University of Technology. The comparative study of different algorithms

is complete, which has allowed the student to submit their Masters

thesis for successful examination. The software tool used in the

research is now being integrated into the bisco product range. It is expected that the tool will be applied into a wide range or

sheet or tiling situations within the build including wall linings,

flooring material, external sheet cladding, and roof cladding.

4. CONCLUSIONS

The success of the material layout optimisation project has led to a

strengthening of the relationship between bisco and AUT, and as a result

further projects are being undertaken with both a short term and a

longer term focus. Of particular note, the success of the material

layout optimisation project has led to another successful grant from

Technology New Zealand to extend the work into new areas, and allowing

the student to enrol for a Doctoral programme. This opportunity will

further increase the value of is research but looking at not only the

impact of sheet layout decisions on the whole building, but to

investigate how the building structure and layout can be modified to

improve the design targets specified by the architect.

At present, one of the key challenges with the bisco software is the

need to address the uptake of the technology with the end users,

particularly mobile users. One of the further projects currently being

undertaken is addressing the usability issues of TabletPC technology and

other mobile devices and address whether this can assist in the

interactions in the supply chain relating to building services

activities.

There is opportunity to further increase the value of this research

by looking at the impact of sheet layout decisions on the building. The

sheet layout determines much of the underlying structure, for example

the placement of studs or joists, and these have a material impact on

the cost of the building. If we can better integrate the decision making

processes that affect the layout of sheeting and the required support

structures the potential should exist to reduce building costs without

reducing the utility value of the structure.

5. ACKNOWLEDGEMENTS

The research outlined in this paper was funded by Technology New

Zealand through the Technology for Industry Fellowships scheme, under

grant number BISC0502.

REFERENCES

Adamowicz, M., & Albano, A. (1976). Nesting

Two-Dimensional Shapes In Rectangular Modules. IEEE Transactions on

Systems, Man and Cybernetics, 8(1), 27-33.

Sibley-Punnett, L., & Bossomaier, T. (2001).

Optimisation techniques for roof layout. Proceedings of IEEE Region 10

International Conference on Electrical and Electronic Technology, 50-56.

Copyright © 2007 Andy Connor, Wilson Siringoringo,

Nick Clements, Nick Alexander

The author(s) assign to NACCQ and educational non-profit institutions a

non-exclusive licence to use this document for personal use and in

courses of instruction provided that the article is used in full and

this copyright statement is reproduced. The author(s) also grant a

non-exclusive licence to NACCQ to publish this document in full on the

World Wide Web (prime sites and mirrors) and in printed form within the

Bulletin of Applied Computing and Information Technology. Authors retain their individual intellectual property rights. |